Contractors often ask me to explain how ground penetrating radar actually sees through solid concrete. It's not magic, and it's not X-ray vision. It's physics—specifically, the behavior of electromagnetic waves when they encounter different materials embedded in concrete.

After scanning concrete daily for over two decades, I can tell you that understanding how GPR works helps contractors recognize both its remarkable capabilities and its practical limitations. This knowledge prevents unrealistic expectations and helps you use GPR effectively for safe concrete work.

How GPR Technology Works

- Electromagnetic waves, not X-rays: GPR transmits radio waves (1,000-2,600 MHz) that reflect when hitting objects with different electrical properties than concrete

- Reflection timing determines depth: Signal travel time calculates object depth—faster return means shallower object, slower return indicates deeper location

- Signal intensity indicates material: Strong reflections suggest metal (rebar, conduits, post-tension cables), weak reflections indicate non-metal or voids

- Frequency creates tradeoffs: High frequencies (2,000+ MHz) provide detail but limited depth; low frequencies (1,000-1,600 MHz) penetrate deeper with less resolution

- Moisture dramatically affects penetration: Wet concrete reduces depth capability by 50-70%—dry concrete scans to 18+ inches, wet concrete often limited to 6-8 inches

- Cannot distinguish materials with certainty: Experienced operators make educated assessments based on patterns, but GPR cannot definitively identify whether metal is rebar vs. conduit vs. post-tension cable

- Dense rebar limits deeper detection: Multiple rebar layers scatter signals, often preventing detection of utilities or post-tension cables located below rebar mats

- Operator expertise matters enormously: Raw GPR data requires skilled interpretation—same scan analyzed by novice vs. expert produces dramatically different accuracy

The Basic Science: Electromagnetic Waves and Concrete

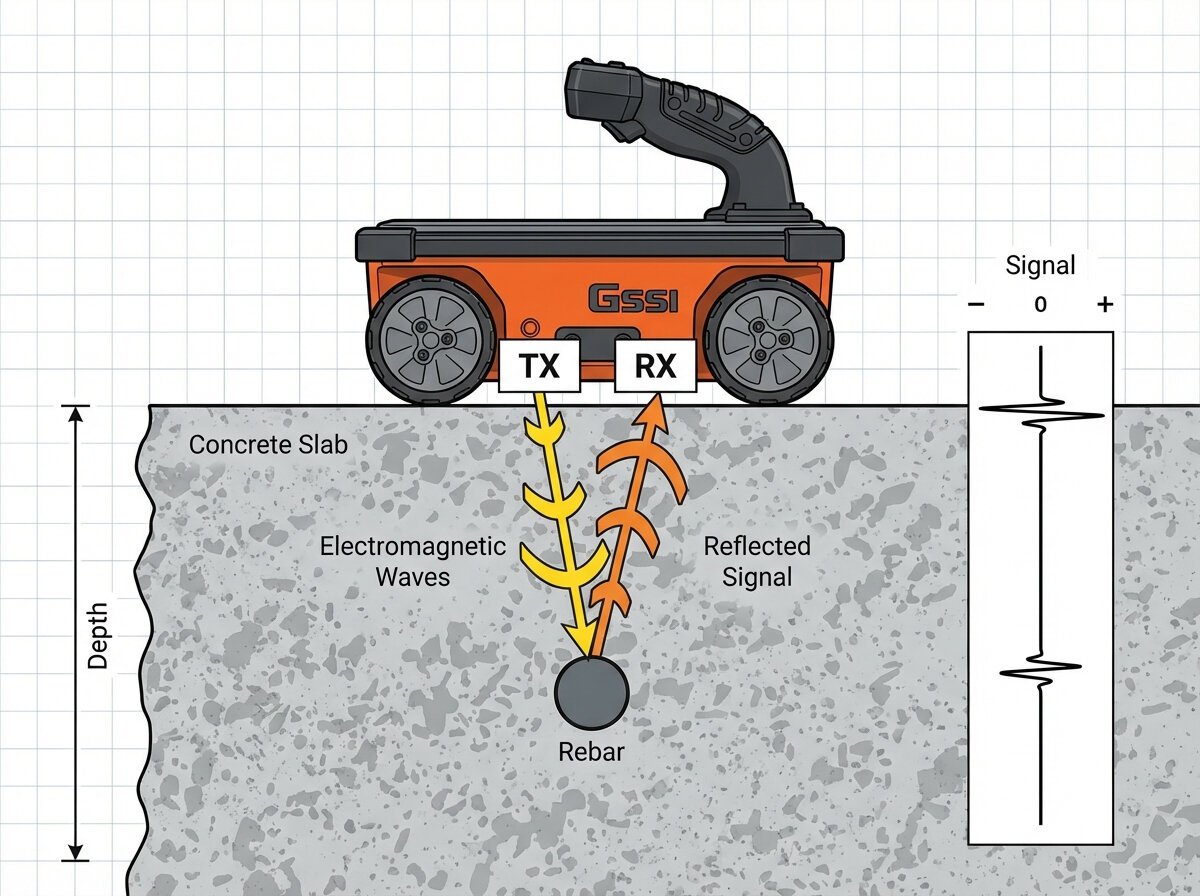

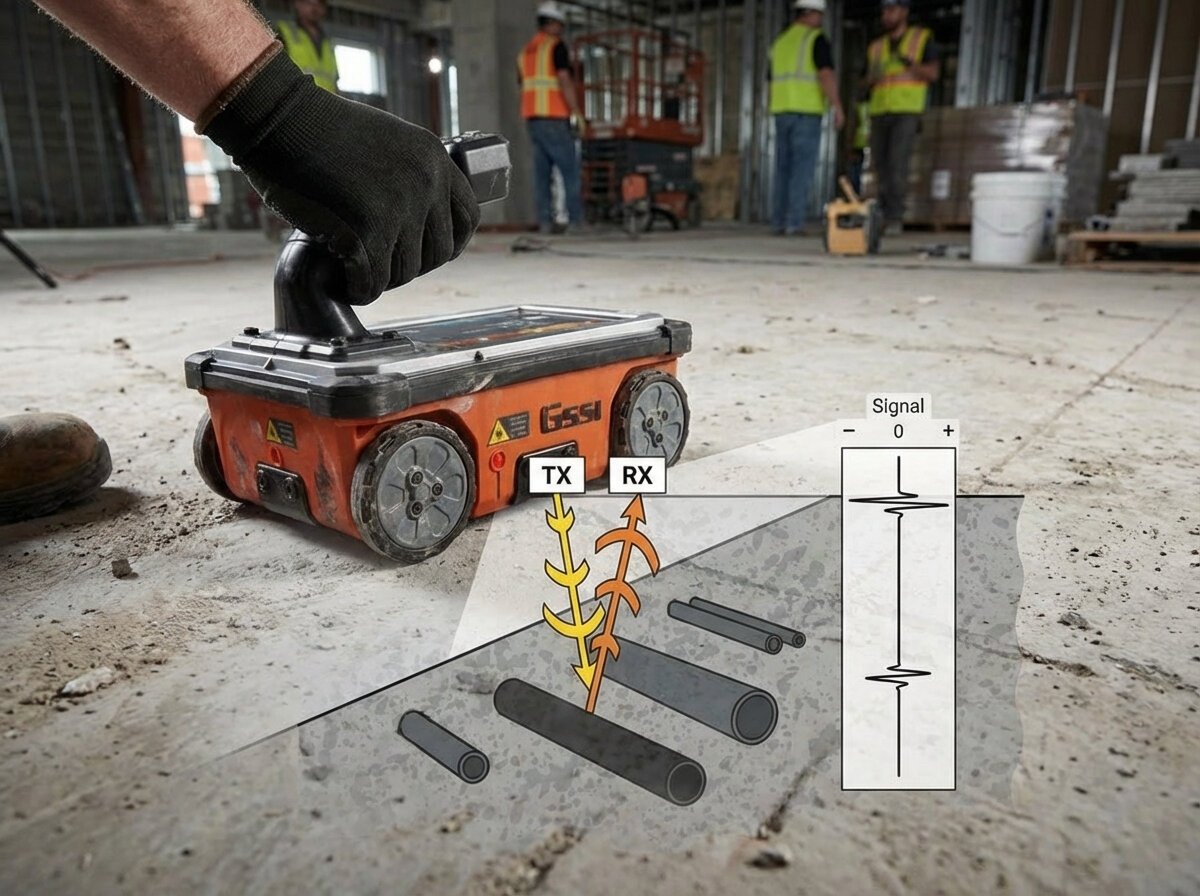

Ground penetrating radar works by transmitting electromagnetic waves—the same type of energy used in radio and WiFi, just at different frequencies—into concrete. When these waves encounter objects with different electrical properties than concrete, part of the signal reflects back to the GPR antenna. The equipment analyzes these reflections to create subsurface images.

The key concept is that different materials conduct electricity differently. Metal objects like rebar, conduits, and post-tension cables conduct electricity well, creating strong signal reflections. Concrete itself conducts electricity poorly, allowing radar waves to propagate through it before encountering embedded objects.

When electromagnetic waves hit a boundary between concrete and metal, much of the signal reflects back instantly. The GPR equipment measures the time between transmission and reception—this timing reveals depth. Signals returning quickly indicate shallow objects, while delayed returns show objects located deeper in the concrete.

Electromagnetic waves transmit into concrete, reflect from embedded objects based on electrical property differences, enabling subsurface detection without physical penetration

Why Metal Shows Up Clearly

Metal objects create the clearest GPR signals because of dramatic differences in electrical conductivity. Steel rebar conducts electricity roughly 1,000,000 times better than concrete. This massive conductivity difference causes strong signal reflections that GPR equipment detects reliably.

Copper conduits reflect signals even more strongly than steel due to copper's superior conductivity. Post-tension cables—steel strands carrying high tension forces—also produce strong reflections. Any metal embedded in concrete creates distinct signals that trained operators recognize immediately in GPR data.

Non-metallic objects like plastic conduits, PVC pipes, or voids reflect signals too, but much more weakly. The conductivity difference between concrete and plastic is subtle compared to concrete and metal. GPR can detect non-metallic objects, but not as reliably or clearly as metal targets.

Frequency Selection: The Fundamental Tradeoff

GPR antennas operate at specific frequencies measured in megahertz (MHz). Concrete scanning typically uses high-frequency antennas ranging from 1,000 MHz to 2,600 MHz. The frequency you choose creates an unavoidable tradeoff between resolution and penetration depth.

High Frequency: Detail at Shallow Depths

Antennas operating at 2,000-2,600 MHz provide excellent resolution for detecting small objects and determining precise locations. These high frequencies work perfectly for shallow targets like rebar located 2-6 inches deep in floor slabs. You can distinguish individual rebar bars, measure spacing accurately, and identify small conduits.

However, high-frequency signals attenuate (weaken) quickly as they propagate through concrete. Penetration depth typically maxes out around 10-12 inches in standard concrete. For shallow rebar locating in typical floor slabs, this limitation doesn't matter—the rebar exists within that depth range anyway.

Professional GSSI equipment like our systems include multiple frequency options, letting us select high frequencies when appropriate for the scanning task.

Lower Frequency: Depth at Reduced Resolution

Antennas at 1,000-1,600 MHz penetrate deeper—typically up to 18+ inches in dry concrete with moderate rebar density. These lower frequencies are essential for detecting post-tension cables, utilities, or objects embedded deeper than typical rebar placement.

The tradeoff is reduced resolution. Lower frequencies cannot distinguish objects as precisely as high frequencies. Individual rebar bars might blur together, and exact depth measurements become less accurate. But for finding deep utilities or post-tension cables where "approximately 14 inches deep" provides sufficient information, lower frequencies deliver necessary penetration.

Experienced operators select frequency based on scanning objectives. Looking for shallow rebar before drilling? Use high frequency. Searching for post-tension cables that might exist 12-16 inches deep? Switch to lower frequency for adequate penetration.

What Affects GPR Penetration Depth

Theoretical maximum depth capabilities mean little in real-world scanning. Multiple factors affect actual penetration depth achieved on any specific project.

Moisture Content: The Primary Limiting Factor

Water conducts electricity far better than dry concrete. Moisture in concrete causes electromagnetic waves to attenuate rapidly, dramatically reducing penetration depth. Dry concrete might allow 18-inch penetration; saturated concrete often limits GPR to 6-8 inches.

This moisture sensitivity creates practical complications. Concrete exposed to rain, humid environments, or water infiltration scans poorly compared to dry interior slabs. Coastal properties in Jacksonville Beach often show moisture effects even in interior concrete due to elevated humidity and salt air.

Contractors sometimes encounter situations where GPR simply cannot penetrate adequately due to moisture. Heavy rain the day before scanning creates unfavorable conditions. We reschedule when possible, allowing concrete to dry for better results.

Rebar Density and Signal Scattering

Dense rebar patterns scatter electromagnetic waves, limiting penetration to depths below rebar mats. A floor slab with rebar at 3 inches depth, followed by post-tension cables at 14 inches depth, presents detection challenges. The GPR signal must penetrate through the rebar mat to reach the post-tension cables deeper below.

Each rebar bar the signal encounters scatters energy. With enough rebar in the signal path, insufficient energy remains to reflect strongly from deeper targets. This explains why heavily reinforced concrete often limits GPR to detecting the shallowest objects—not because deeper objects don't exist, but because rebar above them prevents adequate signal penetration.

Some downtown Jacksonville commercial buildings from the 1980s-1990s feature particularly dense rebar patterns in structural elements. These heavily reinforced members challenge GPR capabilities, sometimes requiring alternative verification methods or extremely conservative cutting approaches.

Concrete Density and Aggregate Size

Dense concrete with heavy aggregate attenuates signals more than lightweight concrete. Aggregate stones create minor signal scattering at the microscopic level—individually insignificant, but cumulatively affecting penetration depth in dense structural concrete.

Lightweight concrete used in some construction applications allows deeper GPR penetration than standard concrete due to lower density and different electrical properties. However, most commercial construction in Jacksonville uses standard-weight concrete where density effects are relatively consistent.

How Operators Interpret GPR Data

Raw GPR data appears as hyperbolic patterns and wavy lines that require trained interpretation. The equipment displays signal reflections over time as the antenna moves across concrete surfaces. Operators must recognize patterns indicating different subsurface features.

Hyperbolic Signatures

Point targets like individual conduits or rebar bars create characteristic hyperbolic (bow-shaped) patterns in GPR data. As the antenna approaches a buried object, signal reflections begin. The strongest reflection occurs when the antenna is directly above the object. As the antenna moves past, reflections continue but weaken. This creates the distinctive hyperbolic shape operators recognize.

Hyperbola depth indicates object depth—deeper hyperbolas mean deeper objects. Hyperbola sharpness suggests object size—sharp hyperbolas typically indicate small targets like conduits, while broader patterns suggest larger objects or object clusters.

Linear Patterns

Continuous linear features like post-tension cables or utilities running parallel to scan lines produce parallel reflection patterns rather than hyperbolas. Operators scanning perpendicular to linear features see distinct hyperbolas; scanning parallel shows continuous lines.

This directionality requires systematic scanning patterns. We scan areas in multiple directions—typically north-south and east-west—to ensure linear features appear clearly regardless of their orientation. Objects oriented parallel to a single scan direction might produce ambiguous signals that become obvious when scanned perpendicular.

Pattern Recognition and Experience

Expert interpretation comes from scanning thousands of concrete structures and developing pattern recognition through daily practice. Rebar shows regular grid patterns with consistent spacing. Post-tension cables appear as parallel lines at specific intervals matching cable layout patterns (typically 4-6 feet apart). Random isolated hyperbolas suggest conduits or utilities.

Novice operators see confusing wavy lines. Experienced operators immediately recognize "that's a rebar mat at 4 inches with post-tension cables below at 13 inches" based on pattern characteristics accumulated through extensive scanning experience.

This expertise gap explains why companies specializing in concrete scanning produce more reliable results than general contractors offering GPR as occasional services. Daily scanning builds interpretation skills that occasional use cannot develop.

Floor marking after GPR scanning shows detected objects—clear marking guides contractors to safe drilling locations avoiding embedded infrastructure

What GPR Can and Cannot Tell You

Understanding GPR capabilities and limitations prevents unrealistic expectations that create problems during projects.

GPR Can Reliably Detect

Metal object presence and location: Rebar, conduits, post-tension cables, and metal utilities show up clearly in GPR data. We mark floor locations showing where metal exists.

Approximate depths: GPR determines depth to within roughly 1/2 inch for shallow targets and 1-2 inches for deeper objects. This accuracy suffices for most construction needs—knowing a conduit exists at "approximately 6 inches deep" lets contractors cut at 3 inches safely.

Object patterns and spacing: Rebar grid patterns, post-tension cable spacing, and utility routing become visible through systematic scanning. These patterns help contractors understand subsurface layout.

Void detection: Air voids beneath slabs or within concrete create weak reflections that trained operators recognize. Voids show up as signal-free zones or characteristic reflection patterns indicating density changes.

GPR Cannot Definitively Determine

Exact object identification: GPR cannot distinguish with certainty whether a metal object is rebar, conduit, or post-tension cable. All metal creates strong reflections. Operators make educated assessments based on depth, pattern, spacing, and construction knowledge—but these are informed interpretations, not absolute identifications.

A hyperbola at 5 inches depth showing typical grid spacing suggests rebar. A parallel line pattern at 14 inches depth suggests post-tension cables. An isolated hyperbola at 8 inches depth suggests a conduit. But these are educated guesses based on probability and typical construction practices, not certainties.

Object size: GPR indicates that an object exists and approximately where, but determining exact dimensions requires additional information. A strong reflection might come from a 1/2-inch conduit or a 2-inch conduit—both create detectable signals, but GPR alone cannot measure precise diameter.

What exists below dense rebar: When heavy rebar mats prevent signal penetration to deeper layers, we cannot reliably state "nothing exists below the rebar." We can only accurately report "rebar visible at this depth; signal attenuation prevents deeper assessment."

Honest communication about these limitations builds contractor trust. Claiming certainty where only probability exists creates liability when reality proves different.

Practical Applications in Jacksonville Projects

Typical Floor Slab Scanning

Standard commercial floor slabs in Southside Jacksonville office buildings typically contain rebar mats at 3-4 inches depth. High-frequency GPR clearly shows rebar patterns, enabling contractors to drill between bars safely.

The process: We scan the area systematically in perpendicular directions. The equipment displays rebar locations in real-time. We mark the floor with spray paint showing rebar grid patterns. Contractors see exactly where rebar exists and where safe drilling zones lie.

This straightforward application represents 60-70% of concrete scanning requests. Contractors need rebar locations, GPR provides them reliably, work proceeds without complications.

Post-Tension Cable Detection

Buildings in downtown Jacksonville constructed from the 1970s-1990s commonly use post-tension concrete systems. These buildings require lower-frequency scanning to penetrate 12-18 inches where post-tension cables typically exist.

We switch to 1,000-1,600 MHz antennas for adequate depth. The tradeoff in resolution doesn't matter—knowing "post-tension cables exist approximately 14 inches deep running north-south at 5-foot spacing" provides sufficient information. Contractors can cut shallow cores at 4-6 inches depth safely, avoiding the tensioned cables below.

Post-tension detection represents critical scanning where consequences of striking cables are catastrophic. A severed post-tension cable can release 60,000+ pounds of force, causing structural failure and $100,000-$500,000 in emergency repairs. This application justifies careful scanning and conservative interpretation.

Utility Location Before Trenching

Medical District facilities often require utility verification before trenching for new plumbing, electrical, or data installations. GPR shows existing utilities embedded in floor slabs, preventing strikes that disrupt critical medical operations.

Medical facility utility strikes create unique complications. Hitting power to surgical areas, data lines for medical imaging equipment, or medical gas systems causes immediate patient care impacts beyond typical commercial disruptions. GPR verification before any cutting becomes mandatory practice rather than optional precaution.

When GPR Encounters Limitations

Conditions Preventing Effective Scanning

Recent rain or wet conditions: Outdoor scanning after heavy rain often produces poor results. Moisture in concrete surface layers dramatically limits penetration. We reschedule when weather permits, or inform contractors that scanning results may be incomplete due to conditions.

Metal surface covering: Metal plates, metal decking, or metal mesh on concrete surfaces block electromagnetic waves completely. GPR cannot penetrate metal—signals reflect from the surface, never reaching the concrete below. Alternative verification methods become necessary.

Heavily reinforced structural elements: Thick walls with dense rebar (common in structural columns, beams, and shear walls) often limit GPR to surface layer detection. We identify rebar patterns visible to GPR, but cannot reliably state what exists in wall cores beyond rebar detection limits.

Being Honest About Limitations

Professional GPR service means acknowledging when conditions prevent reliable scanning. Claiming "we scanned and nothing is there" when moisture or rebar density actually prevented adequate penetration creates dangerous situations.

We explain limitations clearly: "Rebar visible at 4 inches depth, but moisture content prevents deeper assessment. We cannot confirm whether utilities exist below the rebar mat. Recommend cutting to 6 inches maximum depth to stay within verified zone."

This honesty occasionally frustrates contractors wanting definitive "all clear" statements. But accurate reporting of actual detection capabilities provides the information contractors need for safe decision-making—which matters more than providing false confidence.

Professional GPR Scanning Throughout Jacksonville

23+ years technical experience, professional GSSI equipment, honest assessment of detection limitations. Same-day service available.

Call (904) 835-2193Using GPR Effectively

Ground penetrating radar represents powerful technology for subsurface concrete imaging, but effectiveness depends on understanding both capabilities and limitations. The technology cannot do everything—but what it can do, it does remarkably well.

Electromagnetic wave behavior in concrete follows physical principles that create predictable results in favorable conditions. Dry concrete with moderate rebar density scans reliably to 18 inches depth. Wet concrete or dense rebar reduces capability but doesn't eliminate value—knowing rebar locations even when deeper assessment proves impossible still prevents strikes at shallow depths.

Frequency selection, moisture conditions, rebar density, and operator expertise all affect results. Professional scanning means matching frequency to objectives, recognizing when conditions limit reliability, and communicating limitations honestly rather than claiming capabilities beyond actual detection achieved.

The difference between adequate and inadequate GPR service often comes down to operator honesty. Anyone can wave a GPR antenna over concrete and generate data. Professional service requires accurately interpreting what that data actually shows—and what it doesn't show—based on understanding electromagnetic wave behavior and accumulated scanning experience.

For your Jacksonville projects in downtown, Southside, the Medical District, or beachside areas, professional GPR scanning provides reliable subsurface information when operators understand the technology's capabilities and communicate results accurately.

The science works. The equipment performs. But the human expertise in interpreting results and communicating findings honestly determines whether GPR scanning truly protects your projects from the subsurface unknowns that create expensive complications.

That's how ground penetrating radar actually sees through concrete—not through magic, but through applying electromagnetic physics with the experience to interpret results accurately.