Electricians, plumbers, and HVAC contractors working in Jacksonville face a simple reality: cutting into concrete without GPR verification is gambling with your project timeline, your budget, and your liability exposure. The question isn't whether GPR costs money—it's whether you'd rather spend $250-$500 on prevention or $3,000-$100,000+ on emergency repairs.

After watching contractors deal with utility strike consequences for over two decades, I can tell you the ones who prosper use GPR systematically. The ones who struggle skip scanning to save a few hundred dollars, then spend weeks managing the fallout when they hit something they couldn't see.

Why Construction Trades Need GPR

- Prevents catastrophic strikes: Hitting live electrical, water lines, or post-tension cables creates $3,000-$100,000+ repair costs plus project delays

- Protects your liability: GPR documentation proves you took reasonable precautions before cutting—critical if disputes arise about responsibility

- Costs less than one strike: $250-$800 scanning prevents thousands in emergency repairs, overtime charges, and project coordination

- Enables accurate bidding: Knowing subsurface conditions before quoting prevents surprise complications that destroy profit margins

- Same-day availability in Jacksonville: Local providers enable morning scanning, afternoon work—no multi-day delays waiting for verification

- Maintains client relationships: Preventing strikes that disrupt building operations protects your reputation and future referrals

- Required by smart property managers: Professional facilities increasingly mandate GPR in tenant improvement contracts—learn to work with it efficiently

The Real Cost of Skipping GPR

Trades considering whether GPR "costs too much" need to compare scanning fees against actual consequences when strikes occur. The math isn't complicated.

Typical GPR Cost vs. Strike Damage

Professional GPR scanning: $250-$800 for typical trade project verification

Electrical conduit strike: $2,000-$5,000 emergency electrician plus power outage to neighboring tenants, project delays, client complaints

Water line strike: $3,000-$8,000 emergency plumbing plus water damage remediation, tenant disruption, property manager involvement

Post-tension cable strike: $100,000-$500,000 structural engineering, emergency shoring, repairs, evacuations, potential injuries

These aren't theoretical numbers. They represent actual costs contractors face regularly when cutting concrete without verification. And they don't include the time you'll spend coordinating emergency repairs instead of working on paying projects, or the client relationships damaged when your work creates problems for building operations.

What One Strike Actually Costs You

Beyond direct repair bills, utility strikes create cascading costs trades often don't anticipate:

Lost productivity: You stop your current work to manage the emergency. Your crew stands idle while you coordinate repairs. That's billable hours converted to crisis management.

Overtime emergency rates: Emergency electricians or plumbers charge premium rates—often 150-200% of standard pricing. You're paying those premiums because you skipped the $400 GPR scan.

Delay penalties: If your client had timeline requirements with penalty clauses, a strike causing multi-day delays triggers those penalties. Suddenly your "savings" from skipping GPR costs thousands in contractual penalties.

Reputation damage: Property managers and facility engineers remember contractors who cause problems. They don't call you for future work. They warn colleagues about the "guy who hit our main electrical and shut down three floors."

Insurance impacts: Claims for strike damage affect your insurance history. Premiums increase. Some insurers require higher deductibles or exclude certain work types after repeated claims.

How Each Trade Benefits From GPR

Electricians: Avoiding the Unthinkable

Electricians face unique risks. Hitting existing electrical conduits doesn't just create repair costs—it creates immediate danger from live electrical contact. GPR shows where existing electrical infrastructure exists before you cut, drill, or core.

Downtown Jacksonville office buildings often contain dense electrical routing serving multiple floors. Conduits running through floor slabs or walls aren't always where electrical codes suggest they "should" be—previous modifications, non-standard installations, or undocumented changes create surprises.

GPR eliminates surprises. You know where power exists. You route new installations around existing infrastructure. Work proceeds without emergency shutdowns or frantic calls to property managers explaining why three floors lost power.

For tenant improvement work in downtown commercial towers, Medical District facilities, or Southside office parks, GPR verification before cutting becomes standard practice protecting both safety and project timelines.

Plumbers: Preventing Flooding and Worse

Plumbers coring holes through floor slabs for drain routing or vent penetrations risk hitting existing plumbing, electrical conduits, or structural elements. A core drill going through an existing water line creates immediate flooding—water damage remediation costs stack on top of line repair costs.

Worse, hitting electrical while coring creates hazards beyond plumbing scope. Now you've involved electricians in emergency repairs while managing water damage and explaining to property managers why their building has both flooding and power problems.

GPR shows everything in the path of proposed core holes. Existing plumbing appears. Electrical conduits show up. Post-tension cables reveal their locations. You adjust core placement by a few inches, miss all infrastructure, and proceed with work.

The time investment? Typically 30-60 minutes for GPR verification of multiple core locations. The disaster prevention? Immeasurable when you consider flooding scenarios in occupied buildings.

HVAC Contractors: Equipment Installation Protection

HVAC contractors mounting equipment to concrete floors or walls need reliable anchor placement. Anchors drilled into rebar compromise holding strength. Anchors hitting post-tension cables create catastrophic structural risks.

GPR verification before drilling anchor holes ensures you're drilling into solid concrete, not into reinforcement that weakens anchor performance. For heavy HVAC equipment, anchor reliability directly affects safety and code compliance.

Commercial HVAC installations in Medical District hospitals and Southside industrial facilities often involve substantial equipment requiring precise anchor placement. GPR enables confident installation meeting engineering specifications.

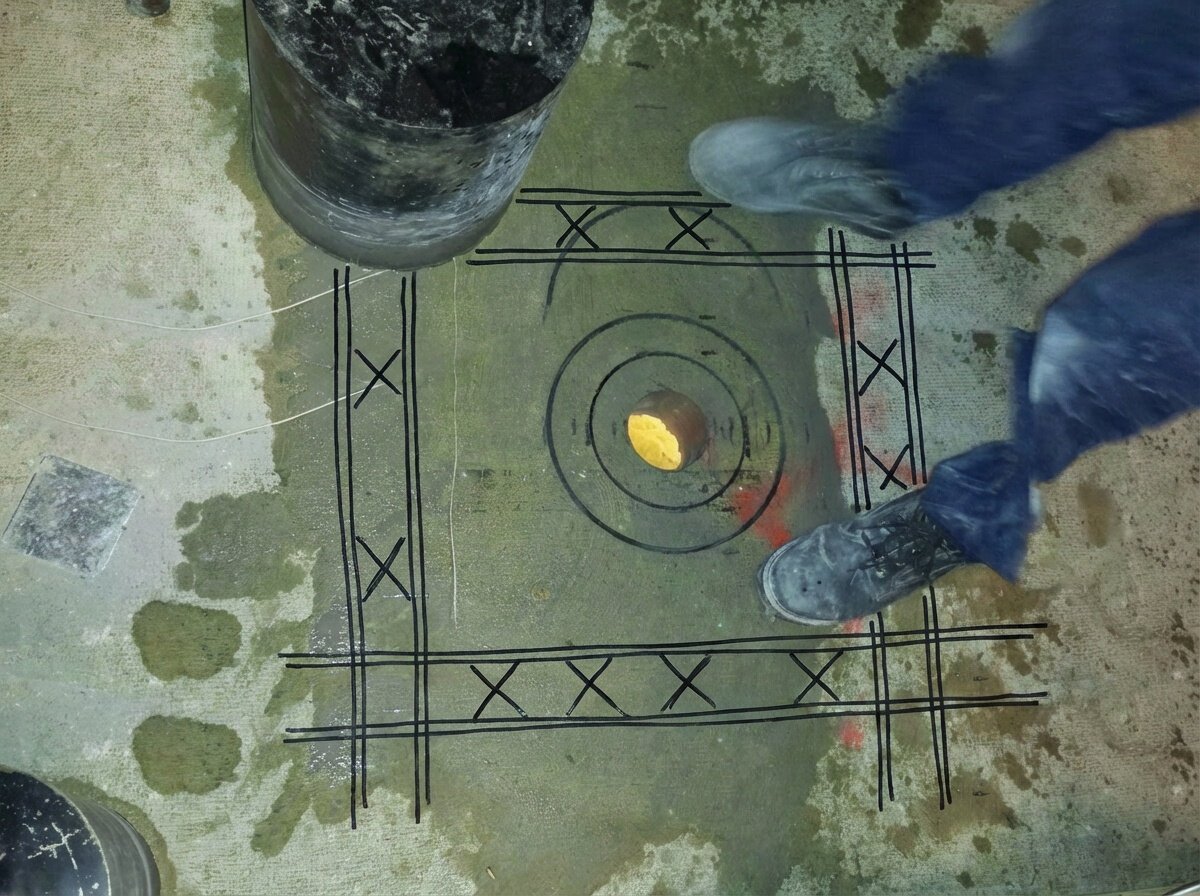

GPR-marked floor shows safe drilling zones avoiding embedded infrastructure—contractors proceed confidently knowing subsurface conditions

How GPR Actually Works on Your Projects

Understanding the GPR process helps trades integrate scanning efficiently into project workflows without creating delays.

The Scanning Process

You identify locations requiring verification—core holes, drill points, cut lines. You call for GPR service. For Jacksonville-based providers like us, same-day service is typically available. Morning call, afternoon scanning, work proceeds same day.

Technician arrives with GPR equipment. We scan designated areas systematically. The equipment shows subsurface conditions in real-time. We mark the floor or wall with spray paint indicating where infrastructure exists.

You receive clear marked locations showing what to avoid. Between marked areas are safe zones for your work. You drill, cut, or core in verified clear zones. No surprises. No strikes. Work proceeds as planned.

Total time impact: 30 minutes to 2 hours depending on project size. Compare this to multi-day delays coordinating emergency repairs after strikes.

What GPR Shows You

GPR detects metal objects reliably—rebar, conduits, post-tension cables, embedded plates. We mark these locations clearly. You see exactly where metal exists and where clear concrete allows safe drilling.

GPR also detects voids, density changes, and non-metallic features, though less reliably than metal. For trade applications, the primary value is locating embedded metal before cutting equipment encounters it forcefully.

One limitation: GPR cannot distinguish with certainty whether metal is rebar versus conduit versus post-tension cable. Experienced operators make educated assessments based on depth, pattern, and typical construction practices. But the bottom line for trades is simpler—metal exists in marked locations, avoid it regardless of specific type.

Making GPR Part of Standard Practice

Building Scanning into Bids

Professional trades include GPR costs in project bids when concrete work is involved. This accomplishes several goals:

Clients understand upfront that professional concrete work includes verification. You're not surprising them with add-on costs after work begins.

You protect profit margins. If your bid doesn't include GPR but competitors' bids do, your "lower" bid becomes higher when you add scanning costs after the fact.

You demonstrate professional practices. Clients appreciate contractors who prevent problems rather than reacting to them. Including GPR in bids signals you operate professionally.

Most importantly, you never face the decision whether to skip scanning to preserve margins. It's budgeted. It happens. Work proceeds safely.

Developing Relationships with GPR Providers

Trades working regularly in Jacksonville commercial construction benefit from established relationships with local GPR providers. Regular clients receive priority scheduling. Providers familiar with your typical projects work more efficiently.

For property managers requiring GPR verification, having a preferred provider you recommend streamlines the process. Rather than each project involving new provider search and coordination, you handle it efficiently through established channels.

Using GPR Strategically

Smart trades don't just use GPR reactively when specifically required. They use it strategically whenever concrete work involves unknowns:

Renovation projects in older buildings where as-built documentation is questionable or absent. You don't know what's embedded—scanning reveals reality.

Projects involving post-tension construction where strike consequences are catastrophic. The modest scanning cost provides insurance against six-figure disasters.

High-visibility projects where client relationships matter more than individual project margins. Preventing problems protects reputation and future opportunities.

Any situation where striking infrastructure creates liability beyond your control—medical facilities, data centers, occupied office buildings where disruptions carry consequences.

Jacksonville-Specific Advantages

Local Provider Benefits

Working with Jacksonville-based GPR providers creates practical advantages distant companies cannot match:

Same-day response: Call morning, scan afternoon, proceed with work same day. Companies traveling from Tampa or Orlando require multi-day advance scheduling plus travel fees.

Zero travel fees: Our $115 call-out covers metro Jacksonville. Companies from Tampa add $500-$1,200 travel charges on top of scanning rates.

Schedule flexibility: Last-minute changes accommodate easier with local providers 20 minutes away versus companies traveling 2-3 hours.

Familiarity with Jacksonville construction: We know local building eras, typical construction methods, and common infrastructure patterns throughout Jacksonville submarkets.

Building Type Experience

Jacksonville construction varies significantly by area and era. Downtown commercial towers from the 1980s-1990s commonly use post-tension systems. Southside industrial buildings feature different reinforcement patterns. Medical District facilities contain specialized infrastructure requiring careful verification.

Experienced local providers recognize these patterns, enabling efficient scanning calibrated to specific building types rather than generic approaches.

Professional GPR for Construction Trades

Same-day service throughout Jacksonville. Zero travel fees. 23+ years protecting trades from utility strikes. Call morning, scan afternoon, work proceeds.

Call (904) 835-2193The Smart Trade Decision

Electricians, plumbers, HVAC contractors, and other trades face straightforward economics: spend $250-$800 preventing problems, or spend $3,000-$100,000+ fixing them after they occur. The math isn't complicated.

Beyond direct cost comparisons, GPR provides less tangible but equally valuable benefits. Sleep better knowing you're not gambling with utility strikes. Maintain client relationships by preventing disruptions. Protect your reputation by demonstrating professional practices.

Property managers and facility engineers notice which contractors prevent problems and which create them. That awareness influences who gets called for future projects. Your GPR usage signals professionalism that wins repeat business.

For trades building businesses rather than just completing individual projects, systematic GPR use becomes competitive advantage. You can confidently bid challenging projects other contractors avoid due to uncertainty. You complete work without the drama and delays that plague competitors skipping verification.

The trades prospering in Jacksonville's competitive construction market don't ask whether they can afford GPR scanning. They recognize they cannot afford to skip it. The modest investment prevents disasters that can destroy project margins, client relationships, and business reputations.

Make GPR part of your standard practice for concrete work. Build it into bids systematically. Develop relationships with reliable local providers. Use it strategically when subsurface unknowns create risks.

Your projects proceed smoothly. Your clients appreciate professional practices. Your reputation grows as the contractor who prevents problems rather than creating them. And you never experience that sinking feeling when cutting equipment hits something you couldn't see.

That peace of mind alone justifies the modest scanning investment. Everything else—the avoided repair costs, the maintained schedules, the protected client relationships—comes as additional benefit.

Smart trades use GPR. Struggling trades explain why they skipped it after disasters occur. Which category describes your approach?