If you're planning to drill, cut, or core into concrete anywhere in Jacksonville, you've probably been told you need ground penetrating radar scanning first. And then someone inevitably asks: "But is GPR actually reliable? Can we really trust what it shows us?"

After 23 years of running concrete scanning projects throughout Northeast Florida—from Southside commercial developments to Medical District hospital renovations—I can tell you the answer isn't as simple as yes or no. GPR reliability depends on several factors, and understanding what those are helps you get accurate results for your project.

What You'll Learn About GPR Reliability

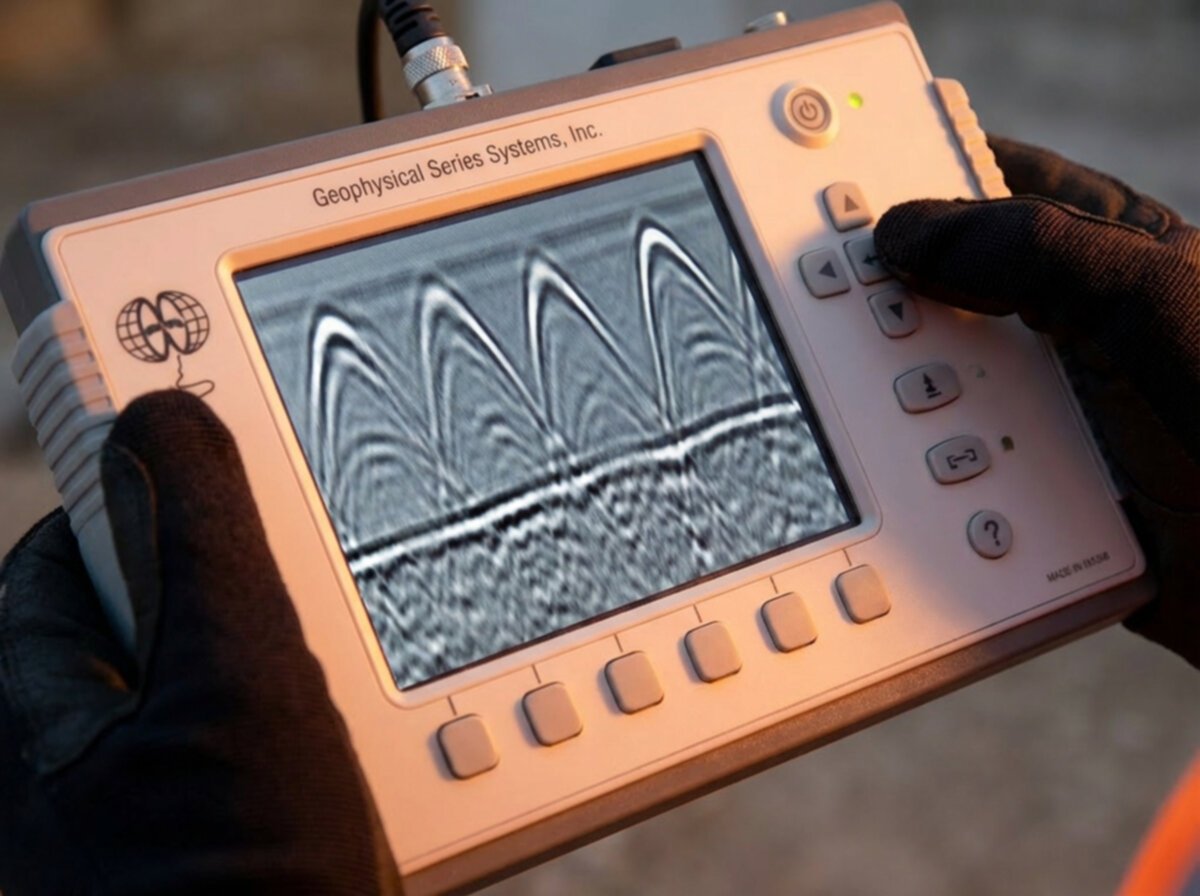

- Equipment quality matters more than you think: Professional GSSI systems deliver consistently reliable results compared to entry-level equipment

- Operator experience is everything: Someone who uses GPR daily produces far more reliable results than someone who does it occasionally

- Site conditions affect accuracy: Moisture content, concrete density, and subsurface materials all influence what GPR can detect

- Specialization matters: Companies that focus exclusively on concrete scanning produce more reliable results than those offering it as a side service

- GPR has proven itself across industries: From archaeology to construction to infrastructure assessment, the technology consistently delivers when properly applied

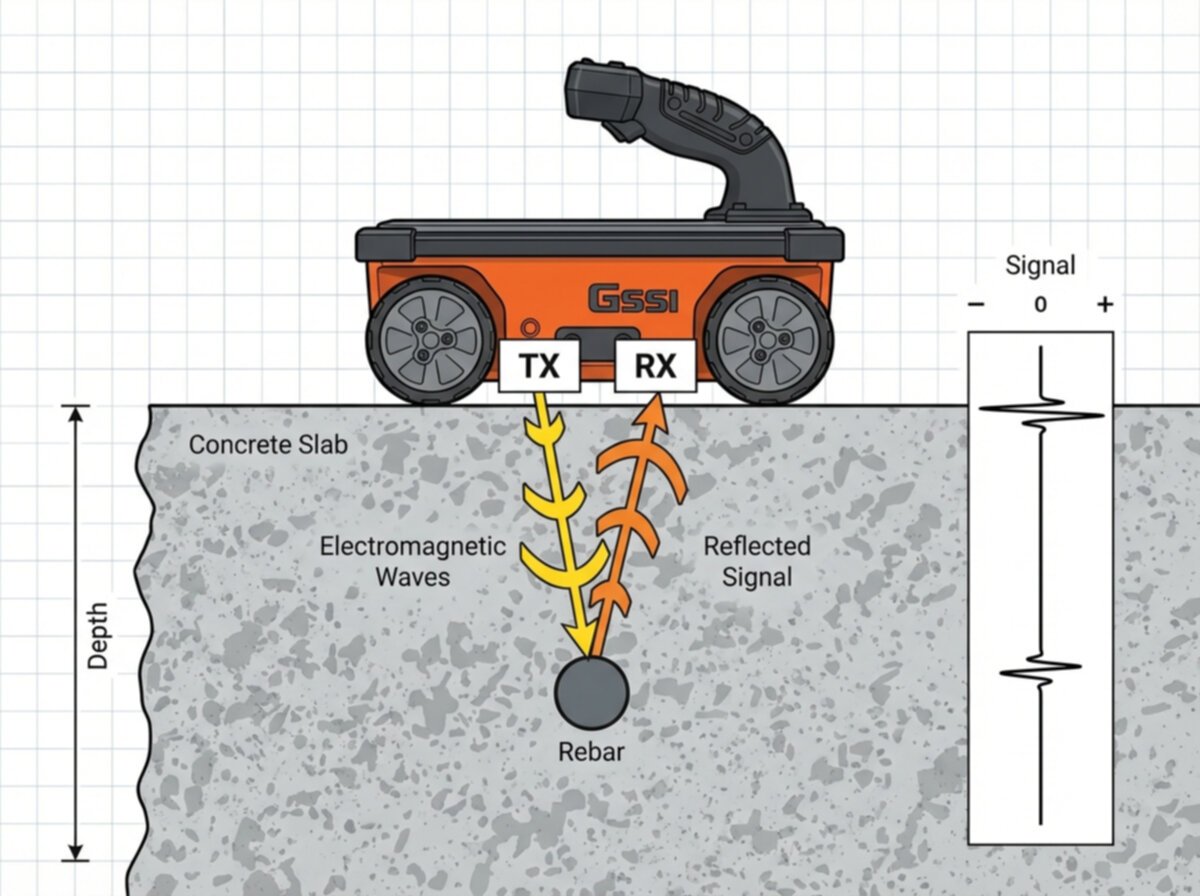

How Ground Penetrating Radar Actually Works

Ground penetrating radar sends electromagnetic pulses into concrete, soil, or other materials. When those pulses hit something—rebar, post-tension cables, conduits, voids, or changes in material density—they bounce back. The GPR equipment measures how long it took for that signal to return and how strong the reflection was, then displays that information on a screen.

Think of it like sonar, but instead of sound waves traveling through water, we're using radio waves traveling through solid materials. The technology itself is straightforward. What makes GPR reliable or unreliable isn't the physics—it's how well the equipment captures those signals and how accurately the operator interprets what they're seeing.

Here's the thing most people don't realize: GPR doesn't show you a photograph of what's underground. It shows you data that needs interpretation. An experienced operator looks at those wavy lines and reflection patterns and knows exactly what they're seeing. Someone without daily experience might miss critical details or misinterpret perfectly normal patterns as something problematic.

GPR technology uses electromagnetic waves to detect subsurface objects, with signals reflecting back to reveal embedded infrastructure

The Science Behind the Reliability

GPR reliability starts with electromagnetic wave behavior. When radio waves encounter a boundary between materials with different electrical properties, some energy reflects back to the receiver while the rest continues deeper. The strength and timing of these reflections reveal information about what's down there.

Different materials affect radio waves differently based on their dielectric properties. Metal objects like rebar and post-tension cables reflect signals strongly—nearly all the energy bounces back, creating clear, high-amplitude reflections on the GPR screen. PVC conduits produce weaker reflections because plastic has lower electrical conductivity than metal, but they're still reliably detectable with proper equipment and technique.

Voids and air pockets create distinct patterns because air has dramatically different electrical properties compared to concrete. This makes GPR particularly effective at identifying delamination in parking structures, voids under slabs, or air gaps behind walls. Changes in concrete density show up as subtle variations in the data—experienced operators recognize these patterns and understand their significance.

The physics behind GPR is straightforward, but applying that physics reliably in real-world conditions requires understanding how multiple factors interact. Concrete moisture content affects signal attenuation. Rebar spacing influences whether individual bars can be distinguished or appear as merged reflections. Depth affects signal strength—deeper objects produce weaker reflections that require careful interpretation to distinguish from background noise.

Professional GPR systems from GSSI (Geophysical Survey Systems, Inc.) use multiple frequencies to capture different types of information. Lower frequencies—typically 400-900 MHz for concrete scanning—penetrate deeper but provide less resolution. You can detect objects at greater depths, but you sacrifice the ability to distinguish closely-spaced features or identify small objects.

Higher frequencies—1500-2600 MHz—show fine detail and clearly resolve individual rebar at tight spacing, but they don't penetrate as deeply. The signal attenuates faster at higher frequencies, limiting effective depth but providing exceptional detail in the upper portions of slabs and walls. The American Concrete Institute (ACI) provides guidelines for GPR application in concrete assessment and quality control.

Knowing which frequency to use for which application is part of what separates reliable results from questionable ones. Scanning a heavily reinforced floor slab at 2600 MHz might beautifully show the top mat of rebar while completely missing deeper post-tension cables. Conversely, scanning at 400 MHz might detect those deep cables but fail to resolve individual rebar clearly enough for precise marking.

Experienced operators often scan with multiple frequencies, combining the depth penetration of lower frequencies with the resolution of higher frequencies to build a complete picture of subsurface conditions. This multi-frequency approach enhances reliability by capturing both shallow detail and deep features in a single assessment.

We can detect inclusions up to 18 inches in normal concrete conditions. Post-tension cables, rebar, conduits, and voids show up clearly at typical construction depths, with post-tension cables often producing stronger reflections than rebar due to their bundled steel strand construction. Detection depends on object size, depth, and surrounding material conditions.

But here's what matters most: detection capability and reliable interpretation are two different things. The GPR equipment detects reflections from subsurface objects—that part is physics, and it works consistently. What determines reliability is whether the operator correctly interprets those reflections, distinguishes actual objects from artifacts, and accurately communicates findings to contractors.

Signal artifacts can create confusion for inexperienced operators. Rebar chairs—the small supports that hold rebar at proper height during concrete placement—create reflections that look superficially similar to actual rebar. Aggregate in concrete produces background patterns that inexperienced operators might mistake for small objects. Multiple reflections from strong targets can create ghost images at false depths.

Daily experience teaches operators to recognize these artifacts and distinguish them from actual features requiring marking. That pattern recognition comes from seeing thousands of scans, comparing GPR data with actual drilling results, and building an intuitive understanding of what different reflection patterns actually mean in concrete construction contexts.

Why Operator Experience Determines Reliability

I've been doing this for over two decades. Every single day I'm looking at GPR screens, interpreting data, marking concrete, and then watching contractors drill, cut, or core exactly where I said was safe. That daily feedback loop—seeing your interpretations proven right or wrong—builds pattern recognition you simply cannot get from occasional use.

When I look at a GPR screen, I'm not just seeing wavy lines. I'm seeing the difference between rebar chairs and actual structural steel. I'm distinguishing between post-tension cables and conduits based on reflection patterns. I'm identifying when moisture is affecting signal penetration versus when I'm looking at genuine depth limitations. I'm recognizing the characteristic signatures of different construction methods and material combinations.

Consider a typical commercial floor slab scanning project. The GPR shows multiple reflection patterns at various depths. An inexperienced operator might mark all strong reflections as "metal present" without distinguishing whether they're looking at upper rebar, lower rebar, post-tension cables, or embedded conduits. They might identify the presence of metal but fail to communicate the specific depths, spacing patterns, and object types that contractors need for safe drilling decisions.

An experienced operator looks at that same data and recognizes the regular spacing pattern characteristic of rebar on 12-inch centers at 2 inches depth, identifies the stronger, deeper reflections as post-tension cables running perpendicular to the rebar at 8 inches depth, and notes the isolated circular reflection as a conduit at 4 inches depth running at a specific angle across the scan area.

That level of detailed interpretation comes from having scanned thousands of similar slabs, having seen how different construction methods produce characteristic patterns, and having verified interpretations against actual drilling results countless times. You can't learn that level of expertise from training courses or occasional practice—it requires daily immersion in the work.

Experience also teaches operators when to slow down and investigate questionable readings more thoroughly. Sometimes a reflection pattern looks slightly unusual—maybe the amplitude is lower than expected for metal, or the depth seems inconsistent with the building's construction era, or the spacing doesn't match any standard construction practice. Inexperienced operators might ignore these anomalies or make assumptions. Experienced operators recognize when something doesn't fit expected patterns and invest additional time verifying their interpretation.

The most critical skill daily experience develops is knowing when you don't know something with certainty. After years of seeing both clear readings and ambiguous data, experienced operators recognize the difference. When data is clear and unambiguous, we communicate confidence. When uncertainty exists—whether due to signal attenuation, conflicting indicators, or unusual construction methods—we communicate that uncertainty honestly and recommend verification approaches.

This calibrated confidence—knowing both what you know and what you don't know—is arguably the most important factor in reliable GPR service. Overconfidence creates problems when operators mark locations as clear despite ambiguous data. Under-confidence wastes contractors' time by requiring verification of perfectly clear readings. Accurate calibration of confidence based on data quality and interpretation certainty is what daily experience provides.

I've trained operators who came to this work with construction backgrounds, engineering degrees, and strong technical aptitude. Even with excellent training and quality equipment, they needed 2-3 years of daily field work before their interpretation reliability matched what experienced operators provide. That learning curve exists because pattern recognition, artifact identification, and interpretation calibration cannot be shortcut—they require repeated exposure to diverse conditions and immediate feedback on interpretation accuracy.

This is why we emphasize hiring firms that specialize in concrete scanning rather than companies that offer it as one of many services. If someone is primarily in the cutting and coring business, they're probably not running GPR equipment daily. Maybe they scan a few times per week, or only when specific projects require it. That occasional use doesn't develop the sharp interpretation skills daily operators maintain.

The difference shows up in project outcomes. Daily operators notice subtle details that occasional users miss. They recognize unusual conditions that require adjusted interpretation approaches. They distinguish between similar-looking patterns that actually represent different subsurface features. And most importantly, they know when data quality or site conditions create uncertainty requiring additional verification—and they communicate that honestly rather than making confident-sounding but potentially questionable interpretations.

Where GPR Proves Its Reliability: Real-World Applications

Construction and Commercial Development

The most demanding test of GPR reliability happens on active construction sites. Contractors need to know exactly where they can drill without hitting anything critical. They're on tight schedules. They're coordinating multiple trades. And they absolutely cannot afford mistakes that shut down work or damage existing infrastructure.

In downtown Jacksonville commercial projects, we've scanned hundreds of locations before contractors installed anchors, cut openings, or cored holes for mechanical systems. The reliability requirement is absolute—you mark something as clear, and drilling equipment goes into that spot within hours. There's no room for "probably" or "I think it's okay."

Downtown commercial buildings present their own reliability challenges. Many structures date to the 1960s-1980s when construction practices differed significantly from modern methods. Older buildings often used construction techniques that create challenging scanning conditions—dense rebar at tight spacing, multiple layers of reinforcement at varying depths, and embedded utilities that weren't always installed according to systematic patterns.

Recent downtown renovation projects have required scanning through challenging conditions created by previous renovations. When a building has been modified multiple times over decades, embedded infrastructure becomes increasingly complex. The original construction drawings show initial rebar patterns and utility routing. But subsequent tenant improvements added electrical conduits, data cables, fire suppression systems, and HVAC penetrations that may or may not appear in updated drawings.

GPR reliability in these complex environments requires both excellent equipment capability and deep experience interpreting layered infrastructure. We've scanned floors where three distinct generations of construction are visible in the data—original 1970s structural systems, 1990s renovation additions, and 2010s technology upgrades. Distinguishing between these layers and accurately identifying what exists at what depth requires pattern recognition that only develops through extensive field experience.

Downtown projects also often involve tight scheduling constraints. Commercial tenants want renovations completed quickly to minimize business disruption. Contractors coordinate multiple trades working simultaneously in limited space. When concrete scanning is scheduled for Tuesday morning and drilling begins Tuesday afternoon, reliability isn't just about accuracy—it's about delivering that accuracy on schedule without delays that cascade through the entire project timeline.

We maintain reliability under these time pressures by having equipment always ready, maintaining local presence for quick response, and employing operators experienced enough to work efficiently without sacrificing accuracy. Some scanning companies can deliver accurate results given unlimited time—they'll scan areas multiple times, research construction methods extensively, and verify every questionable reading before committing to interpretations. That thoroughness is admirable but impractical when contractors need results within hours, not days.

Reliable service in downtown commercial work means delivering accurate results within practical timeframes that keep projects on schedule. This requires operators who can interpret complex data quickly without cutting corners on thoroughness—a balance that only comes from extensive daily experience in similar conditions.

One of our most challenging projects involved a Medical District hospital renovation where surgical equipment needed to be anchored into floors and walls throughout multiple levels. Every anchor location had to be verified clear of post-tension cables, rebar, and existing conduits. We scanned over 200 locations across three months. Zero utility strikes. Zero surprises. That's what reliability looks like in real-world conditions.

Medical facilities present unique challenges that test GPR reliability. Hospitals built in the 1970s and 1980s throughout Jacksonville's Medical District typically employed post-tension concrete construction for floor slabs, combined with dense rebar patterns in walls for structural and seismic requirements. These buildings also contain extensive embedded conduit systems for power, data, medical gas, and specialized hospital systems.

When medical equipment manufacturers require anchor installations for MRI machines, surgical robots, or diagnostic imaging equipment, they specify exact locations based on equipment geometry and utility connections. These locations cannot be adjusted significantly—the equipment must go where the equipment must go. This makes accurate concrete scanning absolutely critical. You cannot simply move an anchor three feet to avoid a post-tension cable when equipment specifications require that exact location.

We've worked on projects at multiple Medical District facilities where each anchor location required verification at specific depths—sometimes 6 inches deep for structural anchors, sometimes 12 inches for specialty equipment. The reliability requirement extends beyond simply identifying metal presence to determining precisely what objects exist at what specific depths. Contractors need to know they can safely drill to 6 inches without hitting anything, even if post-tension cables exist at 8 inches below.

That level of precise depth information requires both excellent equipment resolution and experienced interpretation. Signal reflections don't come with depth measurements printed on them—operators calculate depth based on signal travel time and estimated wave velocity in concrete. Accurate velocity estimation requires understanding concrete properties, which vary based on mix design, aggregate type, moisture content, and age.

In Medical District projects, we typically verify velocity estimates by comparing GPR-indicated depths with known reference points—exposed rebar at construction joints, documented utility depths from as-built drawings, or test measurements at locations where contractors will core regardless. These velocity calibrations enhance reliability by ensuring our depth estimates accurately represent actual subsurface conditions.

The zero-defects requirement in medical facility work validates GPR reliability when properly applied. Hospital administrators cannot accept utility strikes that shut down critical care areas. Medical equipment manufacturers cannot afford installation delays because anchor locations weren't properly verified. And contractors working in occupied hospitals need absolute confidence in scan results to protect both their workers and the facility's patients.

Our success across dozens of Medical District projects—with zero utility strikes and zero required relocations due to scanning errors—demonstrates what reliable GPR services provide when combined with professional equipment and experienced interpretation.

Electrical contractors working on Southside office buildings face similar challenges. They need to route conduit through concrete slabs, sometimes at specific locations dictated by architectural plans. GPR tells them where they can safely cut, where they need to adjust their routing, and where absolutely no cutting can happen. Reliable scanning keeps their projects on schedule and their workers safe.

Infrastructure Assessment and Maintenance

Property managers and building engineers use GPR to assess infrastructure conditions before problems become emergencies. Finding deterioration, voids, or moisture intrusion early saves massive amounts compared to emergency repairs after failures occur.

We've worked with facilities managers throughout Jacksonville Beach commercial properties who use GPR as part of their preventive maintenance programs. They scan parking structures to identify delamination before it becomes a safety hazard. They check for voids under concrete slabs before they become trip hazards or drainage problems. They locate underground utilities before planning landscape modifications.

Jacksonville Beach properties face unique challenges that directly affect GPR reliability. The coastal environment creates conditions significantly different from inland locations just a few miles west. Proximity to salt water accelerates concrete deterioration through chloride intrusion, creating changes in concrete electrical properties that affect GPR signal propagation. Higher ambient moisture from ocean air and elevated water tables influences signal attenuation patterns.

Concrete in beachside structures often contains higher moisture content than similar buildings inland. This moisture affects GPR performance in predictable ways that experienced operators account for in their interpretation. Signals attenuate faster in wet concrete, potentially limiting effective penetration depth compared to dry conditions. However, moisture also can enhance the contrast between concrete and embedded objects, sometimes producing clearer reflections from metallic targets.

Understanding these coastal-specific factors enhances reliability for Jacksonville Beach projects. An operator who primarily works inland might misinterpret reduced signal penetration as equipment limitation or excessive concrete density, when actually they're seeing normal behavior for coastal concrete with elevated moisture content. Local experience recognizes these patterns and adjusts interpretation accordingly.

Beachside parking structures require particular attention because they combine coastal environmental factors with heavy structural loading and extensive embedded infrastructure. These structures typically employ post-tension concrete construction for long spans and durability. They contain drainage systems, electrical conduits, lighting infrastructure, and sometimes heating elements for snow/ice prevention in rare freezing conditions.

We've conducted comprehensive assessments of Jacksonville Beach parking structures, scanning multiple levels to map embedded systems, identify areas of concrete deterioration, and locate voids or delamination before they become safety hazards. These assessments require reliable detection of various features at different depths—from shallow rebar mat at 2-3 inches to deep post-tension cables at 10-14 inches, plus drainage infrastructure and utility conduits at intermediate depths.

The reliability requirement for parking structure assessment differs from typical construction scanning. Rather than verifying single drill locations, facilities managers need comprehensive maps showing infrastructure throughout large areas—sometimes entire parking levels spanning thousands of square feet. This requires systematic scanning coverage, careful data documentation, and clear presentation of findings in formats property managers can use for maintenance planning.

Coastal commercial properties also frequently require utility locating before landscape modifications, site improvements, or building expansions. Underground utilities in sandy soil near the beach create different GPR signatures compared to utilities in heavier clay soils common inland. Sand provides excellent GPR signal propagation with minimal attenuation, but lower dielectric contrast between soil and some utilities can reduce reflection amplitude.

These site-specific considerations demonstrate why local experience enhances reliability. Having worked throughout Jacksonville Beach for over two decades, we understand how coastal conditions affect concrete properties, how beach sand differs from inland soils for utility locating, and how environmental factors unique to beachside locations influence GPR performance. That understanding translates directly to more reliable interpretations for coastal projects.

The reliability requirement here is different but equally important. These aren't emergency "scan it today, drill it tomorrow" situations. These are assessment projects where accuracy matters more than speed. Clients want comprehensive information about conditions throughout their property, and they're making maintenance decisions based on what GPR reveals.

Archaeology and Historical Preservation

While most of our work focuses on construction and infrastructure, GPR's proven reliability extends well beyond those applications. Archaeological projects use GPR to locate buried structures, artifacts, and features without excavation. Organizations like the Archaeological Institute of America recognize GPR as a standard tool for non-invasive site investigation. The technology lets researchers map entire sites, identify promising excavation locations, and preserve historical resources.

The reason archaeologists trust GPR comes down to proven results. When GPR data shows something interesting at a specific depth and location, excavation confirms it's actually there. That consistency—between what the technology shows and what excavation reveals—has established GPR's reliability across thousands of archaeological projects worldwide.

Environmental and Geotechnical Applications

Environmental consultants use GPR to locate underground storage tanks, map contamination plumes, and assess site conditions before development. Geotechnical engineers use it to identify voids, map subsurface stratigraphy, and evaluate soil conditions according to standards established by organizations like the American Society for Testing and Materials (ASTM). Civil engineers rely on GPR for bridge deck assessment, roadway evaluation, and utility mapping.

Each of these applications demands reliable results, and each validates GPR's capabilities in different ways. When a geotechnical report shows a void at a specific location and depth, test boring confirms it. When GPR identifies an underground storage tank, excavation reveals it. When bridge deck scanning shows delamination, core sampling verifies it.

This consistent validation across diverse applications and industries establishes GPR as reliably effective when properly applied with quality equipment and experienced operators.

Professional GPR scanning enables effective coordination between contractors, preventing costly utility strikes and project delays

Understanding What Affects GPR Reliability

GPR doesn't work the same way in every situation. Certain conditions enhance reliability, while others create challenges that require adjustment in approach or interpretation. Understanding these factors helps you know what to expect from concrete scanning on your specific project.

Depth Limitations Are Real But Manageable

People often ask how deep GPR can see. The honest answer: it depends on multiple factors, and deeper isn't always better for reliability.

In typical commercial concrete, professional GPR equipment reliably detects rebar, post-tension cables, and conduits at depths up to 18-24 inches. Beyond that depth, signal strength decreases and interpretation becomes more challenging. But here's what matters more than maximum depth: reliability at the depths you actually need.

Most concrete scanning work in Jacksonville focuses on the upper 12 inches of slabs and walls. That's where the critical infrastructure typically lives—the rebar, post-tension cables, and conduits that contractors absolutely cannot hit. GPR performs exceptionally well at these depths in normal concrete conditions.

When projects require deeper investigation, we adjust our approach. Lower frequency antennas penetrate deeper but show less detail. Multiple scanning passes from different angles provide confirmation. And sometimes we recommend supplementing GPR with other methods like X-ray or ferroscan for verification at extreme depths.

The key to reliability isn't claiming GPR can see unlimited depths—it's knowing the equipment's actual capabilities and working within those parameters while being transparent about limitations.

Concrete Conditions Make a Significant Difference

Not all concrete is created equal from a GPR perspective. Dense, high-quality concrete allows signals to penetrate well and provides clear reflections. Older, lower-quality concrete with high moisture content or significant aggregate variation can attenuate signals and create challenging interpretation conditions.

Jacksonville's coastal environment adds moisture considerations. Concrete near the ocean or in areas with high water tables may contain more moisture, which affects signal penetration. We account for these factors when scanning beachside commercial properties versus inland locations.

Concrete density also matters. Some modern high-performance concrete mixes are so dense they limit signal penetration compared to standard commercial concrete. Conversely, lightweight concrete often provides excellent signal penetration but requires different interpretation approaches.

Experienced operators adjust their scanning approach based on concrete conditions. We might change antenna frequencies, adjust scanning speed, or modify our interpretation criteria based on what the specific concrete conditions allow. That adaptability is part of what makes GPR reliable across diverse project conditions.

Metal Density and Rebar Spacing

The amount and arrangement of metal in concrete significantly affects what GPR can reliably detect. Light rebar at wide spacing provides clear, easy-to-interpret data. Heavy rebar on tight spacing creates a complex reflection pattern that requires skilled interpretation.

Post-tension cables add another layer of complexity. These cables typically sit deeper than rebar and create stronger reflections due to their metal content and construction. But in heavily reinforced concrete with multiple layers of rebar, identifying post-tension cables specifically requires careful analysis of reflection patterns, depths, and signal characteristics.

This is where daily experience separates reliable results from questionable interpretations. Someone who scans concrete occasionally might identify that metal exists without providing actionable information about where contractors can safely drill. We make educated assessments based on reflection characteristics, depth patterns, and spacing regularities to show contractors clear zones versus areas to avoid for coring and cutting operations.

Common Misconceptions About GPR Reliability

"GPR Shows You Exactly What's There Like an X-Ray"

This is probably the biggest misconception I encounter. People expect GPR to produce a photograph showing exactly what's embedded in concrete. That's not how the technology works, and expecting that leads to disappointment or misunderstanding of what GPR actually provides.

GPR shows reflection data that requires interpretation. An experienced operator looks at patterns, signal strengths, depths, and spacing to determine what objects are present and where they're located. It's more like reading an ultrasound than viewing an X-ray—the information is there, but it requires skilled interpretation.

This doesn't make GPR less reliable. It makes operator expertise more important. The data is consistently reliable when you know how to read it properly. That's why we emphasize the difference between equipment capability and interpretation skill.

"GPR Can Identify Exactly What Material Everything Is Made From"

GPR reliably detects objects and shows their location, depth, and approximate size. It shows relative density and produces characteristic reflection patterns for different materials. But it doesn't perform chemical analysis or definitively identify specific materials in every situation.

Metal objects produce strong reflections—rebar, post-tension cables, conduits, pipes all show up clearly as metallic objects. PVC conduits produce weaker reflections than metal but are still reliably detectable. Voids create distinct patterns. Wood produces characteristic reflections different from metal or plastic.

What GPR doesn't reliably do is distinguish between copper pipes and steel conduits, or definitively identify whether a metallic object is rebar versus post-tension cable in every single situation. Experienced operators use context clues—depth, spacing, reflection characteristics, construction methods common to that era and building type—to make informed interpretations about what specific materials they're seeing.

For projects requiring absolute confirmation of material types, we sometimes recommend supplementary methods. But for the vast majority of construction applications—where contractors need to know "where is it safe to drill"—GPR provides reliably actionable information.

"If GPR Doesn't Show Anything, There's Definitely Nothing There"

This misconception runs in the opposite direction and creates a different kind of problem. GPR is remarkably reliable at detecting objects, but no technology is perfect in every situation.

Very small objects near the limits of GPR resolution might not produce clear reflections. Objects at extreme depths beyond equipment capabilities won't show up. Certain material combinations can create signal attenuation that limits detection. And in rare cases, scanning angle or orientation might affect whether an object is clearly visible.

Reliable GPR practice means understanding these limitations and communicating them clearly. When we tell contractors a location appears clear, we're providing information based on thorough scanning with professional equipment and experienced interpretation. But we also acknowledge that limitations exist, and we adjust our approach when projects require absolute certainty beyond what GPR alone can provide.

"All GPR Companies Produce the Same Results"

If GPR were simply a matter of pushing a button and getting automated results, this might be true. But equipment quality, operator experience, and company specialization create substantial differences in reliability.

Entry-level GPR equipment costs $1,500-$5,000. Professional systems like the GSSI units we use cost $25,000-$30,000. That price difference buys signal processing capability, penetration depth, resolution, and data quality that directly affects reliability. You can detect major objects with entry-level equipment, but subtle features, deep objects, or complex conditions require professional-grade systems.

Operator experience matters even more than equipment quality. Someone with 20+ years of daily GPR use interprets data differently than someone who uses GPR occasionally as part of a broader service offering. The pattern recognition, understanding of reflection characteristics, and ability to distinguish between actual objects and signal artifacts comes from thousands of scans over many years.

This is why we consistently recommend hiring companies that specialize in concrete scanning rather than companies offering it as one of many services. The reliability difference shows up in project outcomes—fewer surprises, more accurate marking, better communication about limitations, and results you can trust for critical drilling operations.

What Makes GPR Reliable: The Critical Factors

Professional Equipment From Specialized Manufacturers

We exclusively use GSSI (Geophysical Survey Systems, Inc.) equipment. GSSI has specialized in ground penetrating radar technology since 1970. They don't manufacture cutting equipment, coring tools, or general construction equipment. They make GPR systems, and that focused specialization shows in equipment reliability and performance.

When a manufacturer focuses exclusively on one technology, they develop expertise that translates to better equipment. GSSI systems provide superior signal processing, better penetration depth, higher resolution, and more reliable object detection compared to entry-level systems or equipment from manufacturers who produce GPR as one product line among many.

The GSSI StructureScan series we use represents decades of refinement specifically for concrete scanning applications. The equipment knows how to handle the complex reflection patterns concrete produces. It filters out noise while preserving meaningful signals. It provides display options that help experienced operators make accurate interpretations quickly.

Equipment quality isn't just about fancy features—it's about consistent, reliable performance across diverse project conditions. When we arrive at a downtown commercial building or a Southside industrial facility, we know our equipment will perform reliably regardless of concrete conditions, metal density, or environmental factors.

Could we do concrete scanning with cheaper equipment? Sure. Would the results be as reliable? Absolutely not. That investment in professional-grade equipment is part of our commitment to reliability for every client on every project.

Daily Experience Matters More Than Total Years

I started in this industry in 2002. But the reliability I provide doesn't just come from having 23 years in the business—it comes from using GPR equipment nearly every single day throughout those years. Daily use develops pattern recognition and interpretation skills that occasional use cannot match.

When you scan concrete daily, you see every variation in reflection patterns, every type of construction method, every combination of materials, and every challenging condition multiple times. You learn what rebar looks like at different depths and spacing. You recognize post-tension cable patterns even in heavily reinforced concrete. You identify the subtle differences between conduits, voids, and signal artifacts.

More importantly, you get immediate feedback. You mark locations as clear, contractors drill, and you see whether your interpretation was correct. That feedback loop—repeated thousands of times over years—calibrates your interpretation skills far beyond what training or occasional use can provide.

This is why companies specializing exclusively in concrete scanning produce more reliable results than companies offering scanning as a side service. If you're running GPR equipment every day, you maintain sharp interpretation skills. If you're doing it occasionally between other services, you're essentially relearning the technology each time.

Understanding Site-Specific Conditions

No two concrete scanning projects are identical. Construction methods vary by era, building type, and regional practices. A 1960s office building has different rebar patterns than a 2020s medical facility. Coastal construction differs from inland projects. Industrial facilities use different methods than residential buildings.

Reliable GPR work requires understanding these variations and adjusting interpretation accordingly. When we scan a Medical District hospital built in the 1970s, we know what construction methods were common in that era. We expect certain rebar patterns, typical post-tension cable arrangements, and particular conduit routing methods.

That contextual knowledge combines with the GPR data to produce reliable interpretations. We're not just looking at reflection patterns in isolation—we're considering them in the context of how buildings were actually constructed, what materials were commonly used, and what installation methods contractors employed during that period.

Operating locally in Jacksonville matters. While my primary experience comes from over two decades in the Atlanta market, maintaining local presence in Jacksonville provides same-day response times and eliminates travel fees that distant providers charge. Understanding regional construction practices and coastal environmental factors affecting concrete conditions enhances reliability for Northeast Florida projects.

Proper Scanning Methodology

Reliable GPR results require systematic, thorough scanning methodology. This means multiple passes over each area, scanning from perpendicular directions, adjusting equipment settings for conditions, and verifying questionable readings with additional passes.

When contractors need a single core location verified, we scan that area from multiple directions. When a project requires marking an entire floor for anchor locations, we establish a systematic grid pattern and methodically scan every section. When conditions challenge interpretation, we slow down, make additional passes, and adjust our approach until we're confident in our results.

Some companies rush through scanning to maximize billable hours per day. We prioritize accuracy over speed. Taking the time to scan thoroughly, verify questionable readings, and ensure complete coverage provides the reliability contractors need for critical drilling operations.

Clear Communication About Capabilities and Limitations

Reliability isn't just about accurate scanning—it's about clear communication. When we can definitively identify objects and mark locations with high confidence, we say so clearly. When conditions create uncertainty or limitations exist, we communicate that honestly.

Some scanning companies overpromise capabilities to win projects, then underdeliver on accuracy. We take the opposite approach: clearly communicate what GPR can and cannot reliably show in specific project conditions, explain any limitations upfront, and recommend supplementary methods when projects require certainty beyond what GPR alone provides.

That transparency builds trust and ensures contractors make informed decisions. They know what our scanning can reliably show them, they understand where uncertainties exist, and they can plan their work accordingly. Reliability requires both accurate data and honest communication about that data.

How to Ensure Reliable GPR Results on Your Project

Ask About Equipment and Manufacturer

When evaluating concrete scanning providers, ask what equipment they use and who manufactures it. Professional operations use systems from specialized GPR manufacturers like GSSI, Sensors & Software, or IDS GeoRadar. These companies focus exclusively on ground penetrating radar technology and produce equipment designed specifically for reliable concrete scanning.

Entry-level equipment from general electronics manufacturers might cost 1/3 the price of professional systems, but they provide dramatically different capabilities. If reliability matters for your project—and it should—verify your scanning provider uses professional-grade equipment from manufacturers who specialize in GPR technology.

Verify Company Specialization

Companies that specialize exclusively in concrete scanning develop expertise and maintain equipment specifically for that purpose. Their operators use GPR daily, building the interpretation skills necessary for reliable results. Their business model depends on accuracy, so they invest in training, equipment, and methodologies that ensure reliability.

Companies offering concrete scanning as one of many services—cutting, coring, utility locating, general construction—spread their expertise across multiple disciplines. Their operators might use GPR occasionally rather than daily. Their equipment might be entry-level systems sufficient for basic applications but inadequate for challenging conditions.

Ask potential providers what percentage of their business focuses on concrete scanning. Ask how many days per week their operators actively scan concrete. Ask about operator experience specifically with GPR interpretation. The answers reveal whether you're hiring specialists or generalists.

Request Information About Operator Experience

Technology reliability means nothing without operator expertise. Ask how long specific operators have been interpreting GPR data. Ask how many scans they perform monthly or annually. Ask about their experience with your specific building type, construction era, or project conditions.

Operators with 10+ years of daily GPR use interpret data differently than someone with general construction experience who learned GPR basics in a training course. That interpretation expertise directly affects reliability for your project.

Understand Response Times and Service Areas

Reliability includes being available when contractors need scanning. Local providers based in Jacksonville can typically respond same-day for urgent projects and accommodate schedule changes more easily than companies traveling from Tampa, Orlando, or Atlanta.

Response time matters especially on active construction sites where schedules shift, weather delays push work, or last-minute issues require additional scanning. A scanning company based locally maintains flexibility that distant providers cannot match. For more details on how location affects service delivery, see our guide on RADAR imaging companies serving Jacksonville.

Ask About Limitations and Supplementary Methods

Reliable providers communicate clearly about GPR limitations and recommend supplementary methods when appropriate. If a scanning company claims GPR shows everything with perfect accuracy in all conditions, they're either uninformed or dishonest.

Professional providers explain what GPR can reliably detect in your specific project conditions, acknowledge where uncertainties might exist, and suggest additional verification methods when projects require absolute certainty. That honest communication is part of reliable service.

The Future of GPR Reliability

GPR technology continues evolving. Modern systems provide better signal processing, improved penetration depth, higher resolution, and more sophisticated data displays than equipment available even 10 years ago. These advances enhance reliability by providing operators with better information for interpretation.

Artificial intelligence and machine learning show promise for automated interpretation assistance. Future GPR systems might identify common objects automatically, flag unusual patterns for operator review, or provide interpretation suggestions based on analysis of thousands of previous scans. These technologies could enhance reliability by augmenting human expertise with computational pattern recognition.

However, technology advances won't eliminate the importance of operator experience. Automated systems might assist with interpretation, but understanding construction methods, recognizing context clues, and making judgment calls in ambiguous situations still requires human expertise developed through years of field experience.

The companies that provide the most reliable GPR services in the future will combine advancing technology with deep operator expertise—using new tools to enhance human interpretation rather than attempting to replace the judgment skilled operators provide.

Integration With Other Technologies

GPR increasingly integrates with complementary technologies. Real-time 3D visualization helps operators and clients better understand subsurface conditions. GPS and positioning systems enable precise location mapping. Digital reporting tools provide comprehensive documentation. Cloud-based data storage allows project teams to access scan results remotely.

These integrations enhance GPR's practical reliability by improving how scan data is captured, displayed, shared, and documented. Contractors get clearer information about exactly where objects are located. Project managers can review scan results remotely. Building owners maintain permanent digital records of subsurface conditions for future reference.

Making the Right Choice for Your Jacksonville Project

GPR reliability comes down to three factors: professional equipment, experienced operators, and specialized focus. When all three align, GPR provides remarkably reliable subsurface information for construction, infrastructure assessment, and project planning throughout Jacksonville and Northeast Florida.

We've built our business exclusively around concrete scanning because specialization produces reliability. Our operators use professional GSSI equipment daily, developing expertise that occasional users cannot match. We understand Jacksonville construction methods, local building materials, and regional factors affecting concrete scanning. And we've proven our reliability through thousands of successful projects where contractors drilled exactly where we marked as safe—with zero surprises.

Whether you're planning major construction in the Medical District, renovating downtown commercial properties, maintaining Southside facilities, or developing beachside projects, reliable GPR scanning protects your project from costly utility strikes, keeps work on schedule, and ensures worker safety.

The technology is reliable. The question is whether you're working with providers who use professional equipment, employ experienced operators, and specialize in delivering accurate results. Those factors determine whether GPR provides the reliability your project needs.

Experience Reliable GPR Services in Jacksonville

Over 23 years of RADAR imaging expertise. GSSI equipment. Daily field experience. Same-day response throughout Northeast Florida with zero travel fees.

Call (904) 835-2193The Bottom Line on GPR Reliability

Is ground penetrating radar reliable? Yes—when you have professional equipment, experienced operators, and realistic understanding of what GPR can and cannot show.

GPR reliably detects rebar, post-tension cables, conduits, voids, and other subsurface features at typical construction depths in normal concrete conditions. It consistently provides the information contractors need to drill, cut, and core safely. And it has proven this reliability across thousands of projects, multiple industries, and diverse applications over decades of real-world use.

What makes GPR unreliable is inadequate equipment, inexperienced operators, or unrealistic expectations about capabilities. Entry-level systems produce questionable results in challenging conditions. Occasional users miss details that daily operators recognize immediately. And expecting GPR to perform beyond its actual capabilities leads to disappointment.

After 23 years of daily GPR use throughout Jacksonville and Northeast Florida, I trust the technology completely—not because it's perfect in every situation, but because I understand its capabilities, work within those parameters, and communicate limitations clearly when they exist.

That combination of proven technology, specialized expertise, and honest communication provides the reliability construction projects demand. Your drilling operations stay on schedule. Your workers stay safe. And your projects avoid the costly surprises that utility strikes create.

If you're planning construction, renovation, or infrastructure work anywhere in Northeast Florida, reliable concrete scanning starts with choosing providers who specialize in this technology, use professional equipment daily, and stake their reputation on accuracy.

We've proven our reliability on projects ranging from single core locations to comprehensive facility assessments. We maintain that reliability through continued investment in equipment, ongoing operator training, and unwavering focus on accuracy over volume. And we're available when Jacksonville contractors need reliable subsurface information—typically same-day for urgent projects, with zero travel fees and the flexibility that only local providers maintain.

The technology is reliable. Make sure you're working with reliable providers who can deliver the accuracy your project demands.